Choosing the Perfect Forklift Type for Your Operations

Forklifts are the backbone of logistics in factories, warehouses, and construction zones. These machines aren’t just helpful. They’re workhorses built for lifting, towing, and neatly stacking massive loads that no human ever could. They make hard labor lighter, faster, and safer.

But here’s the catch: choosing the right forklift is not nearly as simple as pointing at one in a catalog. The wrong choice can slow down your workflow. Or worse, it can even put people at risk.

Choosing the Perfect Forklift Type for Your Operations

Your forklift is the tool that turns plans into completed tasks. Choosing one is like selecting the right cog in a massive machine. A single mismatch throws the whole thing off balance.

It’s not just about lifting power. It’s about finding a seamless fit between the machine and your daily workflow. A mismatch can create workflow bottlenecks. It can even raise fuel and maintenance costs. Worse, it can cause product damage and increase accident risk.

On the flip side, picking the right forklift can mean an immediate boost. Tasks become smoother, teams work faster, and energy costs go down. Most importantly, your workplace becomes a safer environment.

This guide aims to take the guesswork out of forklift selection. We’ll explore their load capacity, terrain capability and fuel types. We also discuss their mast options and attachments. With this knowledge, you can pick the right forklift to match your exact needs.

Why Choosing the Right Forklift Matters

Many companies underestimate the impact of getting forklift selection wrong. The price tag is only the first expense. The real costs show up later.

Reduced Productivity

A forklift that’s too small for your loads will strain under pressure and slow down operations. Meanwhile, one that’s too bulky will be a nightmare to maneuver. You’ll end up wasting plenty of time while reducing output.

Higher Maintenance Costs

Overloading a forklift or using it on wrong terrain leads to faster parts wear out. That eventually shortens the machine’s lifespan and drives up maintenance costs. Industry research from the Material Handling Industry (MHI) shows improper use can raise maintenance costs by up to 25%.

Safety Risks

This is the big one. Overloaded or misused forklifts can tip. Rough terrain can throw them off balance. Poor visibility increases collision risk. According to OSHA reports, forklift accidents in the U.S. claim about 85 lives and seriously injure nearly 35,000 people each year. That is a red flag.

Many of these incidents are preventable. So, take the time to determine exactly what you need before you invest.

Ultimately, this isn’t just about saving money. It’s also about building a safe jobsite environment.

Key Factors to Consider

Picking a forklift begins with three questions. How will you use it? Where will it operate? What tasks will it need to perform?

Load Capacity

Different Forklifts for Different Weights

Electric Forklifts (Class I) are great for indoor tasks. They typically handle loads from 3,000 to 15,000 lbs.

Gas or Diesel Forklifts are the heavy-duty options for outdoor work. Some models lift over 35,900 lbs. Smaller internal combustion (IC) trucks handle up to 5,000 lbs and run on LP or gas. Larger ones (6,000 lbs and above) are available in LP, gas, or diesel.

Reach Trucks are designed for lighter loads, usually ranging between 2,000 lbs to 5,500 lbs. They’re great at stacking high in warehouses.

Overloading is Dangerous

Overloading can cause tip-overs, mast damage, or motor burnout. Stability and safety depend on using the right machine for the job.

Figure Out What You Need

Weigh your heaviest load, with the pallet included. Choose a forklift that can comfortably lift beyond that. This extra capacity gives you a margin of safety and helps the machine last longer.

Terrain and Environment

A forklift’s operating environment matters just as much as its lifting capacity.

Indoors (Smooth Floors)

Go with cushion tires. These solid rubber tires are perfect for warehouse floors. Pair with an electric forklift for clean and quiet operation.

Outdoors (Rough Terrain)

Standard forklifts sink or stall on loose gravel or soft dirt. Rough Terrain Forklifts (RTFL) perform better in such environments. RTFLs, like those from Loadlifter, are specially designed with high-clearance suspension and rugged tires. Many operators compare them to backward tractors because of their build.

Slopes or Tight Spaces

Tight aisles demand forklifts with excellent maneuverability. Steep ramps require powerful engines and secure braking systems.

Lift Height and Reach

If you need to stack high, the forklift’s mast type becomes a critical factor.

Standard Mast is for low-level lifting

Duplex (Two-Stage) gives you a bit more height.

Triplex (Three-Stage) reaches even higher, often used in warehouses with tall racking.

Quad (Four-Stage) provides maximum reach for specialized storage setups.

For warehouses with multi-tier shelving, reach trucks or turret trucks are built for very narrow aisles and tall storage.

Fuel Type and Power Source

Your choice of fuel affects emissions, operating costs, and where you can use your forklift.

Electric Forklifts

Pros

Clean, quiet, and ideal for indoor use. Low operating costs and minimal maintenance.

Cons

Higher upfront cost. Limited by charging time unless you have spare batteries.

Best for

Food storage, indoor logistics, and noise-sensitive environments.

Pros

Flexible for both indoor and outdoor use. Quick refueling. Lower emissions than diesel.

Cons

Requires proper storage for gas cylinders. Emits some fumes. Fuel prices may fluctuate.

Best for

Mixed-use facilities needing flexibility and fast turnaround.

Diesel Forklifts

Pros

Built for heavy loads. Refuels quickly and handles tough outdoor jobs with ease.

Cons

Loud, emits fumes, and unsuitable for indoor use unless well-ventilated. Diesel prices can spike.

Best for

Large-scale outdoor operations, construction, and industrial settings.

Work Cycle and Usage Frequency

Frequency of use is also a deciding factor. Daily, heavy-duty use calls for a different model than one used occasionally.

Heavy-Duty (Continuous Use)

Electric or LPG models are solid choices, depending on environment and runtime needs.

Occasional Use

If it’s more of a part-time role, lighter models work fine. Basic electric units or pallet jacks are cost-effective and low-maintenance solutions. LP trucks are also less expensive to purchase upfront. For applications under 4 hours a day, a quality used forklift can offer great value.

Attachments & Versatility

Forklifts aren’t limited to just forks. Using attachments like carton clamps, paper roll clamps, rotators, and side-shifters can expand its functionalities. Take note, however, that each attachment can affect your machine’s weight capacity.

Common Forklift Types and Their Ideal Uses

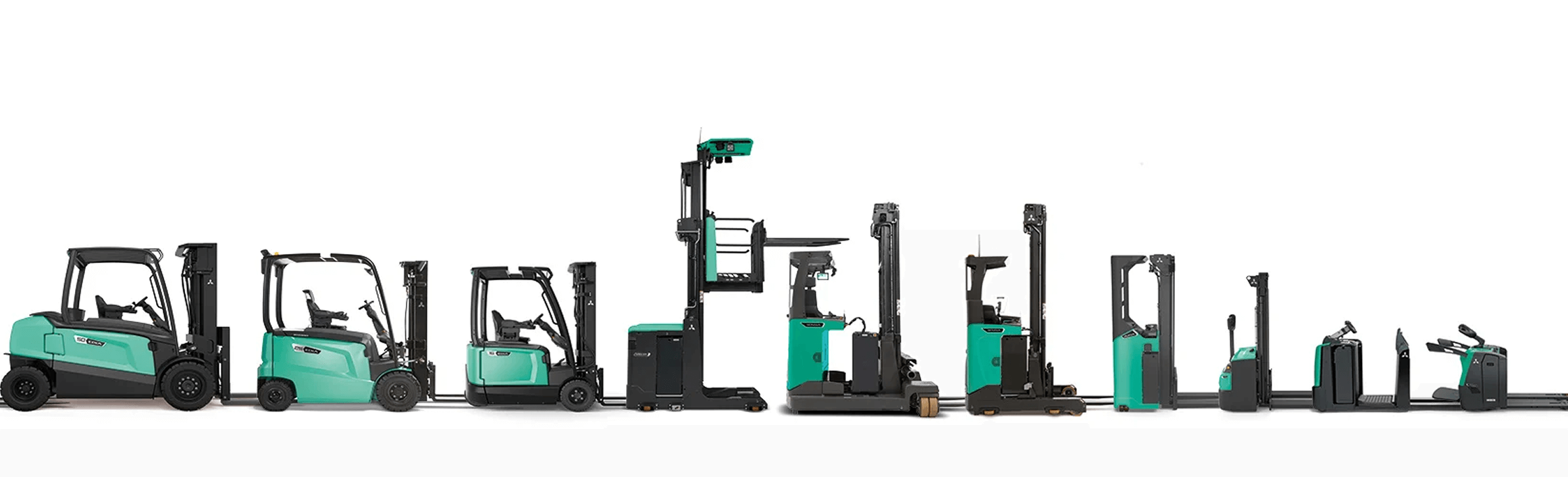

Reach Trucks

Ideal for high storage in narrow aisles. Their extending masts allow precision picking and stacking.

Best for: Cold storage, vertical warehouse setups, and any tight space.

Pallet Jacks / Walkie Stackers

Simplified tools for floor-level movement. Walkie stackers can do minor lifts.

Best for: Light loads, retail stockrooms, and compact warehouses.

Order Pickers

These lift operators grab items directly from shelves.

Best for: E-commerce and distribution centers where individual items (not full pallets) are picked regularly.

Equipped with telescopic arms and versatile attachments, telehandlers handle everything from light tasks to heavy lifts.

Best for: Versatile lifting in retail, warehouses, and tight spaces.

Rough Terrain Forklifts

With heavy-duty suspension and big tires, these thrive on uneven outdoor surfaces.

Best for: Construction sites, lumberyards, and muddy fields where regular forklifts would sink or stall.

Narrow Aisle Forklifts (Turret or Articulated)

Turret trucks rotate their forks to access both sides of an aisle. Articulated forklifts bend in the middle for tight turns.

Best for: Dense warehouse environments with slim aisles and vertical storage demands.

Note: Don’t confuse telehandlers with Aerial Work Platforms (AWPs). Telehandlers lift loads using forks or attachments, while AWPs lift people for overhead access.

Matching Forklift Type to Your Business Needs

With the groundwork laid, let’s look at how real businesses match forklifts to their workflow:

Scenario 1: E-commerce Fulfillment Center

Needs: High lifts, compact navigation, item-level picking, zero emissions.

Solution: Use Reach Trucks for pallets and Order Pickers for individual items. Both should be electric.

Scenario 2: Outdoor Construction Operation

Needs: Load-heavy equipment, rough terrain, long reach.

Solution: Combine Rough Terrain Forklifts with Telehandlers, both diesel-powered for rugged reliability.

Scenario 3: Small Factory with Limited Usage

Needs: Occasional pallet transport, indoor-friendly, compact.

Solution: A small Electric Counterbalance Forklift plus a Pallet Jack for quick moves.

Your Forklift Checklist

Ask yourself:

- Will I use the forklift indoors or outdoors? This determines tire type and fuel system.

- What’s the heaviest load to lift? Always include the pallet’s weight.

- Do I have narrow or wide-open aisles? Measure spaces before buying.

- How high must I lift? Know your top shelf’s exact height.

- Will I use it all day or just sometimes? This affects your power choice.

- What’s the terrain like? Smooth, uneven, wet, or sloped?

- Do I need attachments? Some options include paper clamps, rotators, and side-shifters.

Picking the right forklift isn’t about grabbing the biggest, newest, or cheapest option. The real goal is to have a safe, efficient machine that perfectly matches your project’s needs.

→

→