Forklifts are the backbone of the Material Handling Industry. Forklift use ranges from small retail beverage distribution to seaport shipping containers transportation. With capacities ranging from as low as 3,000 lbs to as much as 35,000 lbs, sit down, gas forklifts are the powerhouses of any lifting operation.

Gas Forklift: Backbone of Any Operation

Pneumatic Tire

Pneumatic tire forklifts are the cornerstone of any fleet that works outside or on mixed surface conditions. First-rate maneuverability and top-notch lift and lowering speeds make it a breeze for your operation to get the job done.

Cushion Tire

Cushion tire forklifts are the go-to choice when operating indoors and on smooth surfaces. Built to handle a wide range of industries, these trucks move loads that aren’t limited to just bulky materials such as lumber, construction material, containers, palletized finished goods, barrels and drums. They move what needs to be moved, when it needs to be moved.

Electric Forklifts: A New Wave of Efficiency

More than ever before, businesses are turning to electric forklifts for their material handling needs because they don’t produce harmful emissions, yet feature similar performance to their internal combustion counterparts.

Three-wheel electric trucks run clean and quiet. Wherever emissions and noise are undesirable, these forklifts are among your best choices. Each forklift is designed to help deliver more power, more functions and more reliability for your money. Lifting capacities range from 2,200 lbs to 6,500lbs.

AC MOTOR

AC control systems deliver performance and efficiency. Following the operator’s command, the two-stage hydraulic system determines the optimum motor speed, resulting in reduced energy consumption and longer battery life.

SERVICEABILITY

Electric forklifts main controllers are easily accessible, usually located at waist height, reducing service time. Uncomplicated removable side battery compartments allow for quick battery maintenance.

Electric Stand Up Order Picker Forklifts

Order picking is one of the most controlled processes in warehouse management and is not a one-size-fits-all process. It is a basic warehousing process that has an important influence on supply chain productivity.

Order pickers come in multiple variations to match your style of picking. Piece-picking or zone picking methods generally require a powered lift such as a high, medium or low level stand up order picker to complete order preparation. In many low-level applications, a powered pallet jack truck may be a better option than using a foot picker. Lifting capacities range from 2,200 lbs to 3,000 lbs.

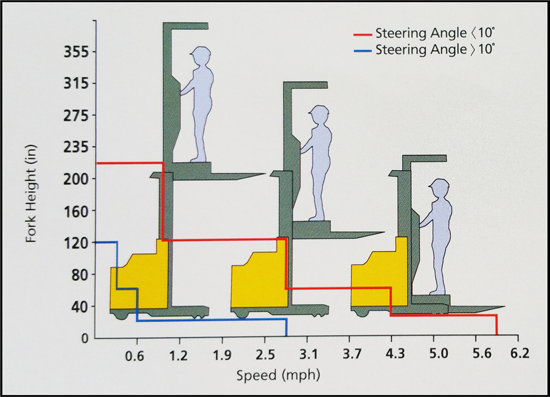

Turning Radius

A stand up electric order picker’s compact design makes it suitable for narrow aisle operation, guaranteeing work efficiency and maximum space utilization with its minimized turning radius.

Customizable

Many order pickers allow for great flexibility with a large range of chassis and cabin width options, as well as operator height options. Customization packages include “The Workplace Comfort Package” offers LED internal cabin lighting, LED work lights and an operator fan, while the optional key pad allows operators to engage the order picker through a unique PIN number.

Electric Reach Truck

If you are looking to maximize warehouse space, reach trucks are right up your alley. AC reach trucks operate effortlessly in aisles well below 10 feet in width, letting you get at those really hard-to-reach assets. With a fully electric power steering system, reach trucks are quieter and easier to control than hydraulic steering systems, providing the precision necessary for tight turns in confined areas. Lifting capacities generally range from 2,500 lbs to 4,500 lbs.

Options

SERVICEABILITY

Reach trucks boast 500-hour service intervals, helping you save on maintenance costs with less downtime for service.

These forklifts are backed by some of the industry’s best services, delivering you great value and peace of mind.

Electric Pallet Jack

Electric pallet jack trucks are meant for the indoors, where travel is short, work spaces are congested and floor loading is common. These jacks maneuver exceptionally well in confined work areas and can move a variety of loads.

Pallet jack construction include components that provide smooth fast operation while keeping maintenance costs low. Electric pallet jack trucks are tough and highly productive. Lifting capacities of electric pallet jacks, pallet stackers, and walkies generally range from 2,200 lbs to 6,000 lbs.

Maneurverable

Electric pallet jacks feature short head lengths and a tight turning radius to maneuver in areas that require pin-wheeling or right angle stacking. Many lifts have the ability to move with the handle in a fully vertical position, making it easy to operate in confined spaces.

Comfortable

Standard electric pallet jacks and walkies come with a low mounted handle to maximize the distance between the operator and the tractor, which provides an additional measure of safety during operation. As a result, steer effort is significantly reduced and the handle offers large, easy to reach fingertip controls.

Pallet Jack

The pallet jack is the most basic of material handling equipment. It is intended to move heavy or light pallets in a warehouse setting. Hand pallet jacks thrive in a variety of applications, being used by operators of all experience levels.

Maneuverable and easy-to-use, these lifts are a dependable source for moving materials in your application. Lifting capacities of pallet jacks are 5,000 lbs.

Smooth Operation

A hand pallet jack’s smooth performance and handling is a result of its low rolling resistance polyurethane steer and load wheels. Adjustable pushrods on the reinforced c-channel forks resist twisting under heavy loads, making the pallet jack easy-to-use in a variety of applications.

Rugged & Solid

Engineered from thick homogeneous steel, the pallet jack frame features temperature-controlled robotic welds to maintain material strength and powder coat pain for additional protection in tough applications. The cast iron, one-piece pump features polyurethane seals at high pressure points to help ensure your load gets off the ground quickly.

Is Your Forklift Operation OSHA Safety Compliant?

According to OSHA forklift compliance requirements, it is the responsibility of the employer to make sure that any employee, temporary or permanent, that operates a forklift receives forklift safety training.

Forklift training requirements include:

- Formal instruction. The employer can create their own forklift training and be compliant with OSHA requirements.

- Practical training. Either demos by the instructor and exercises practiced by the student. Training needs to be specific to the workplace and to the type of equipment that they will be expected to use.

- Evaluation. Assessment of the operator’s performance in the workplace.